New Products

Find Magnetic Drum Separator For Sale, Metal Separation Equipment, Magnetic Roller Separator on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Delivery Time: | 15 Days |

Model No.: CTB918

Magnetic Roller Separator is a mineral separator that's mainly used for mineral contained iron content, according to its working condition, it can be divided into wet magnetic separator and dry magnetic roller separator, as it needs to add water for the wet magnetic separator while the dry type is no need.it is mainly used for iron ore such as magnetite ore, hematite ore, and some river sand, lake sand and some slags processing.

Classification of Magnetic roller separator / Metal separation equipment

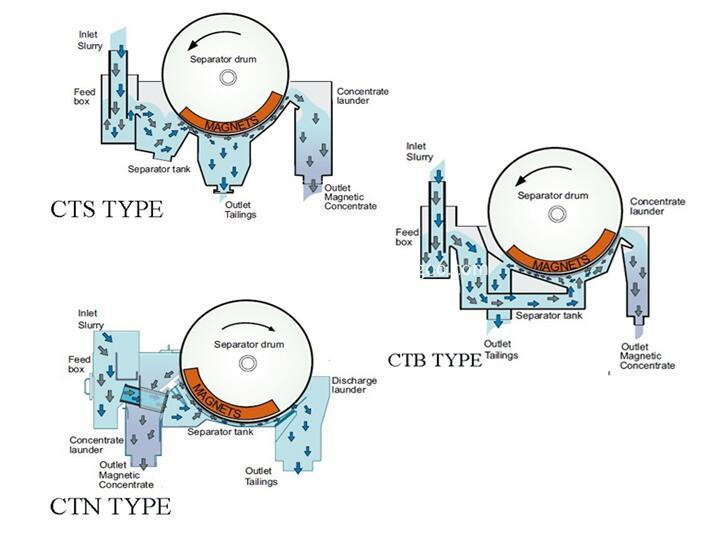

Wet drum magnetic separator is suitable for strongly magnetic mineral. According to tank structure pattern can be divided into co-current, half-countercurrent, and countercurrent 3 kinds.

Co-current type magnetic separator ( CTS) characteristics advantages: have a large capacity, suitable for processing coarse granularity (0-6mm) strong magnetic materials selection and selection can also work more than one thread. Disadvantages: when Co-current magnetic separator is fed more capacity iron ore, magnetic mineral particles easily lost in the tailings, so to strengthen the operational management and control to be a low pulp level.

Countercurrent type magnetic separator (CTN) characteristics advantages: with a higher recovery rate, suitable for fine-grained (0-1.5mm) strong magnetic minerals roughing and scavenging operations. Disadvantages: to get lower concentrate grade. Because coarse-grained material easy to plug the sorting room, so countercurrent-type magnetic separator does not be suitable for dealing with coarse-grained materials.

Advantages of half-countercurrent type magnetic separator (CTB) characteristics: to get high-quality iron ore concentrate, and better recovery, it is suitable for processing 0.5-0mm of the mineral particles, so half-countercurrent magnetic separator is widely used in different kind of industry. Mingyuan can produce different types magnetic drum separator for sale

| Model | Shell diameter(mm) | Shell length(mm) | Shell rotation speed(r/min) | Feeding size(mm) | Processing capacity(t/h) | Power(kw) |

| CTB6012 | 600 | 1200 | ‹35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | ‹ 35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | ‹ 35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | ‹ 35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | ‹ 35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | ‹ 28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | ‹ 20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | ‹ 20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | ‹ 20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | ‹ 18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | ‹ 18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | ‹ 18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | ‹ 14 | 3-0 | 170-280 | 11 |

Product Categories : Beneficiation Equipment > Mineral Separator